Wondering how to sand quartz? You’ve come to the right place; this comprehensive guide will walk you through the essential steps and techniques needed to achieve a smooth, polished finish on your quartz surfaces.

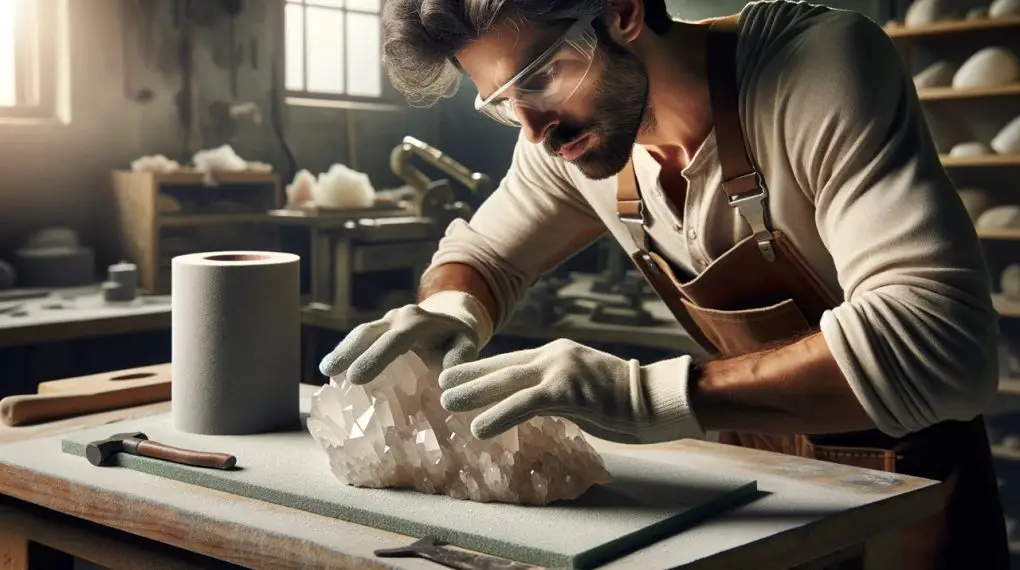

Step 1: Prepare Your Workspace

Before you begin, it’s essential to prepare your workspace to ensure both safety and efficiency. Start by choosing a well-lit area with sufficient natural or artificial light.

Good lighting is crucial for accurately seeing the quartz’s surface texture and identifying any imperfections that need sanding.

Clean your workspace thoroughly. Remove any dust, debris, or tools unrelated to your quartz sanding task. A clean area will help prevent any foreign particles from interfering with the sanding process.

Ensure proper ventilation in your workspace. Sanding quartz can generate fine dust particles, which can be harmful if inhaled over time. Working in a well-ventilated area, or even outdoors if possible, can significantly reduce this risk.

Place your quartz material on a stable, flat surface. This could be a sturdy workbench or table. If the quartz piece is small, consider using a vise or clamps to securely hold it in place during the sanding process. This prevents the quartz from moving and ensures more precision in your work.

Gather all the necessary tools for the task. This includes:

Sandpaper of varying grits: Start with a lower grit for initial sanding and gradually move to higher grits for finer finishing.

A sanding block: This will help you apply even pressure during sanding and can prevent uneven surfaces.

Safety goggles: Protect your eyes from any quartz dust or small particles generated during sanding.

A dust mask or respirator: To protect your lungs from fine dust particles, use a dust mask or a respirator, especially if you’re working in a less ventilated space.

Step 2: Choose the Right Sandpaper

Selecting the appropriate sandpaper is a pivotal step in the process of sanding quartz. The grit of the sandpaper determines how much material it will remove and how smooth the finish will be.

Sandpaper grit refers to the size of the abrasive particles on the paper. A lower grit number means coarser sandpaper with larger abrasive particles, which removes more material. Conversely, a higher grit number indicates finer sandpaper with smaller particles for a smoother finish.

Step 3: Wet Sanding Technique

Wet sanding is a highly recommended technique when working with quartz. This method not only reduces the amount of dust produced during sanding but also contributes to a finer, more polished finish on the quartz surface. Here’s a detailed breakdown of how to effectively implement the wet sanding technique:

Prepare for Wet Sanding: Before you start, ensure that your workspace is suitable for wet sanding. As this process involves water, it’s important to protect any sensitive materials or tools in your workspace. If you’re working on a wooden bench, for instance, consider laying down a waterproof cover.

Water as a Sanding Aid: The primary purpose of using water in wet sanding is to minimize dust and keep the sandpaper and quartz surface free from accumulating debris. The water acts as a lubricant, reducing friction and helping to achieve a smoother finish.

Dip Sandpaper in Water: Begin by dipping your chosen grit sandpaper in water. You can also use a bowl or tray of water for this purpose. Ensure the sandpaper is adequately soaked; this helps it to conform better to the quartz surface and prevents dust from becoming airborne.

Use a Spray Bottle: Alternatively, or in addition to dipping, keep a spray bottle handy. Regularly spray the quartz surface and the sandpaper during sanding. This keeps both the surface and the paper sufficiently wet, ensuring the effectiveness of the wet sanding process.

Step 4: Sand in Consistent Motions

Sanding in consistent motions is crucial for achieving a uniform finish on your quartz surface. This step focuses on the technique and rhythm you should maintain while sanding.

Proper technique ensures that you remove material evenly and avoid creating new scratches or irregularities on the quartz surface. Here’s a more in-depth look at how to execute this step effectively:

Choose Your Sanding Pattern: While there are various sanding patterns, using even, circular motions is particularly effective for quartz. These motions help distribute pressure uniformly and minimize the risk of creating grooves or uneven areas.

Maintain Gentle, Consistent Pressure: Applying too much pressure can lead to uneven sanding and potentially damage the quartz. Instead, use a light but steady pressure.

Let the sandpaper do the work rather than forcing it. This consistent pressure helps in achieving a smooth, even finish.

Focus on Uniform Coverage: As you sand, be mindful of covering the entire surface area of the quartz. Pay special attention to edges and corners, ensuring they receive the same amount of sanding as the rest of the surface.

Rinse the Sandpaper Frequently: Quartz dust can build up on the sandpaper, reducing its effectiveness. Regularly rinse the sandpaper to clear away this dust.

If you’re dry sanding, tap the sandpaper gently to remove the dust. If you’re wet sanding, dip the sandpaper in water or use a spray bottle to rinse it off.

Check Your Progress Often: Periodically stop sanding to inspect the surface of the quartz. Feel it with your hands for any rough spots or inconsistencies. Look at it from different angles and under good lighting to check for scratches or uneven areas.

Change Sandpaper When Needed: As sandpaper wears down, its effectiveness decreases. Change to a new piece of sandpaper when you notice it’s no longer performing as well. This is especially important when working with finer grits.

Be Patient and Methodical: Sanding requires patience. Rushing through this process can lead to mistakes and an unsatisfactory finish. Take your time and focus on maintaining your technique throughout the sanding process.

Minimize Dust Spread: If you’re dry sanding, use a dust collection system or a simple vacuum cleaner with a brush attachment to minimize the spread of quartz dust in your workspace.

Step 5: Progress Through Grit Levels

After using the coarser grit, clean and inspect the quartz surface. Ensure that the most significant scratches or rough patches have been adequately smoothed out. This inspection is crucial before moving on to finer grits.

Move to Medium Grits: Next, transition to a medium grit, such as 400. This grit continues to smooth the surface but is less abrasive than the coarser grit. It starts to refine the work done by the previous sandpaper and prepares the surface for even finer sanding.

Consistent Sanding Technique: Maintain the same consistent, circular sanding motions you used with the coarser grit. This consistency is key to achieving a uniform surface without creating new scratches.

Progress to Fine Grits: After the medium grit, move to finer grits like 600. This stage is more about polishing than shaping. You’re now removing the finer scratches left by the previous grits and beginning to bring out the quartz’s natural shine.

Final Polishing with Very Fine Grits: The final step in the grit progression involves using very fine grits, such as 800 or higher. This stage is about achieving that glass-like finish. The sanding here is more delicate and requires a gentle touch and patience.

Regularly Check Your Work: At each grit level, stop and check your progress. Look for uniformity in the finish and ensure that scratches from the previous grit stage are adequately removed before moving on to a finer grit.

Keep the Surface Clean: Between each grit change, clean the quartz surface with a dry rag to remove any residual dust. This prevents contamination of the finer grit sandpaper with coarser particles, which could scratch the surface.

Patience and Attention to Detail: As you move through each grit level, take your time. The finer the grit, the more attention to detail it requires. This gradual progression is not about rushing but about meticulously refining the surface for the best possible finish.

By carefully progressing through grit levels, you ensure a gradual and controlled smoothing of the quartz surface, leading to a polished and professional-looking finish. This step-by-step approach is key to achieving the best results in your quartz sanding project.

Step 6: Final Touches

After wiping it down, dry the quartz thoroughly with a clean, dry cloth. This step is essential to remove any moisture that could interfere with the application of polish or sealer.

Inspect the Quartz: Before moving on to polishing or sealing, inspect the quartz surface closely. Look for any missed spots or areas that might need a bit more sanding. If you find any, it’s better to address them now before applying any finishing products.

Choose the Right Quartz Polish or Sealer: There are various products available specifically designed for quartz. These can enhance the shine and provide a protective layer.

When selecting a polish or sealer, opt for one that is suitable for quartz and follow the manufacturer’s instructions for the best results.

Apply the Quartz Polish/Sealer: Apply the polish or sealer evenly across the surface of the quartz. Use a soft cloth or a specific applicator recommended by the product manufacturer. Apply in a smooth, circular motion to ensure even coverage. Avoid applying too much product, as this can lead to streaks or an uneven finish.

Buff for Extra Shine: Once the polish or sealer has been applied, and had time to set (if required by the product instructions), buff the surface with a clean, soft cloth. This will enhance the shine and ensure a smooth, even finish.

Final Inspection: After buffing, step back and inspect the quartz from various angles and under different lighting conditions. This will help you see if you’ve achieved the desired level of shine and if the surface is uniformly treated.

Optional: Apply a Second Coat: Depending on the product used and the desired level of shine and protection, you might consider applying a second coat of polish or sealer. If so, repeat the application and buffing process as before.

Step 7: Clean Up and Maintenance

Completing your quartz sanding project with a thorough clean-up and proper maintenance of your tools ensures a safe and efficient workspace for future projects.

Quartz dust can have health implications if not handled correctly, so it’s crucial to follow these steps to minimize any risks:

Thorough Workspace Cleaning: Start by thoroughly cleaning your workspace. Remove any quartz particles and dust from your work surface, tools, and surrounding areas.

Using a vacuum cleaner with a fine dust filter can be highly effective in capturing the small particles. Make sure to clean any dust collection systems or filters in your vacuum as well.

Wet Cleaning for Residual Dust: After vacuuming, use a damp cloth to wipe down all surfaces, including any equipment and the floor around your work area. Wet cleaning helps capture any remaining fine dust that the vacuum may have missed.

Safe Disposal of Quartz Dust: Collect the quartz dust and dispose of it safely. Due to its potentially harmful nature when inhaled, ensure it’s sealed in a bag or container before disposing of it.

Check with local waste management guidelines to see if there are specific disposal methods for such materials.

Tool Maintenance: Clean your tools thoroughly. Wash any sanding blocks, brushes, or other tools that have come into contact with the quartz or dust. Dry them completely to prevent rust or deterioration.

Store Tools Properly: Once your tools are clean and dry, store them in a proper place. Organizing your tools not only prolongs their life but also ensures that they are easy to find and ready to use for your next project.

Personal Protective Equipment (PPE) Care: Clean your safety goggles, dust mask, or respirator, and any other protective gear you used. Inspect them for any damage and store them properly. Proper care of your PPE ensures they remain effective for future use.

For more articles on sanding, click here: Sanding: Your Full-Circle Guide to Smooth Mastery

Conclusion: How to Sand Quartz

Successfully sanding quartz is an art that combines skill, patience, and attention to detail. From preparing your workspace to the final touches and clean-up, each step plays a crucial role in achieving a polished and professional finish.

By starting with the right sandpaper grit and progressing through to finer levels, you methodically smooth and refine the quartz surface. The wet sanding technique further enhances this process, minimizing dust and maximizing smoothness.

The key to success lies in the consistency of your technique and the patience with which you approach each stage. Sanding in even, circular motions and maintaining gentle, consistent pressure ensures uniformity in your work.

The final touches, including cleaning, polishing, and sealing, bring out the natural beauty of the quartz, leaving it with a lustrous and appealing finish.

Remember, the meticulous clean-up and maintenance of your workspace and tools not only preserve your health and safety but also prepare you for future projects. Each step, when executed with care and precision, contributes to the overall success of your endeavor.